Description

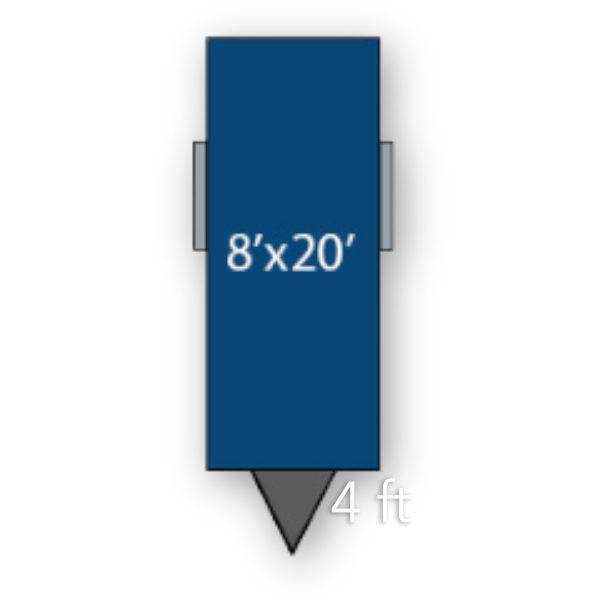

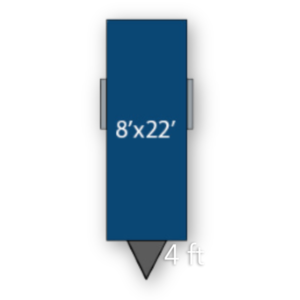

Dimensions: 8′ W x 20′ L food trailer with a double 7,000 lb straight axle (+4.5′ tongue)

Tires and Safety: E-Rated (10-Ply) trailer tires, safety chains, electric brakes, and breakaway kit in compliance with DOT regulations

Interior Features: Stainless steel counters, cabinets, and shelves with aluminum supports

Lighting: Equipped with (3) 4′ LED fixtures

Electrical Panel: 125 Amp, 12-Space, two 4-Circuit Type-BR Outdoor Main Lug Sub Feed Panel with a 50 Amp/240 Volt power inlet

Water System: 80-gallon fresh water tank, 135-gallon grey water tank, on-demand water pump with accumulator, fresh water inlet, and direct water inlet in a lockable box (bypasses fresh water tank)

Sanitation: NSF-approved handwashing sink with soap and paper towel dispensers

Entrance: 36″ W x 72″ H (rough opening) main entrance door

Comprehensive Trailer Plan

Structural Features

Subframe: 3″ I-Beam cross members on 12″ centers with 4″ long rail. Mylar tape is applied between all-steel subframe components and extruded aluminum lower bottom rails for corrosion prevention.

Flooring: 1-⅛” laminated hardwood floorboards secured with two countersunk screws per board at each cross member, in a staggered pattern. Floorboards are ship-lapped and pre-undercoated for weather protection, with .063 aluminum tread plate overlay, welded seam on the floor with 6″ base and ⅜” radius coving.

Side Skins: .040 aluminum side panels secured with rivets.

Side Wall Structure: Extruded aluminum top and bottom rails with 1-⅜” deep galvanized steel z-shaped vertical posts on 16″ centers.

Front End: Aerodynamic aluminum radius, steel z posts, and .040 aluminum secured with rivets.

Roof: .032 one-piece aluminum sheet with anti-snag roof bows on 24″ centers, crowned design for water and ice drainage, with aluminum radius and poly-tuff corner caps.

Exterior Lighting: Tecniq S34 LED clearance lights per FMVSS-108, installed on front corner caps, side top rails, and rear header. Includes LED turn signals and LED license plate lights.

Interior Walls: ⅝” plywood secured to galvanized steel z-shaped vertical posts with 1″ foam insulation in the walls (front and side), and triple-layer ⅝” plywood on the back wall. .24 quilted stainless steel panels adhered to the plywood walls.

Ceiling: Insulated ceiling with 1″ foam and .24 quilted stainless steel sheets, attached to framing on 24″ centers.